Diesel generator (Introduction-I)

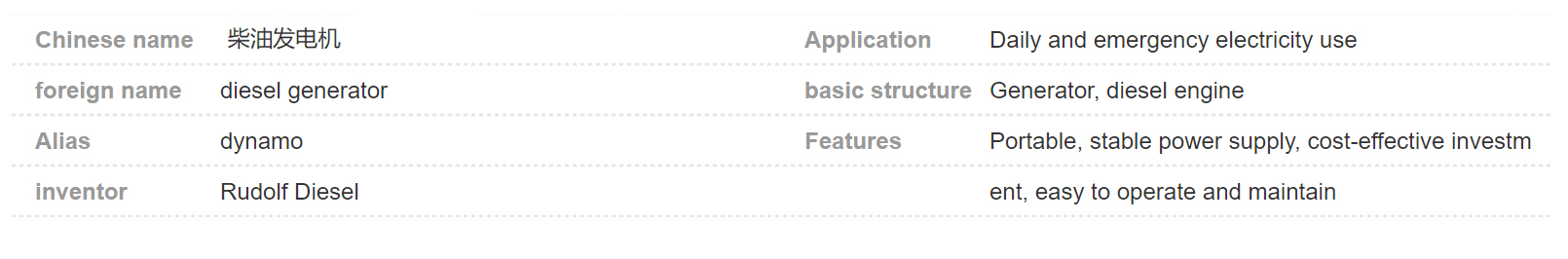

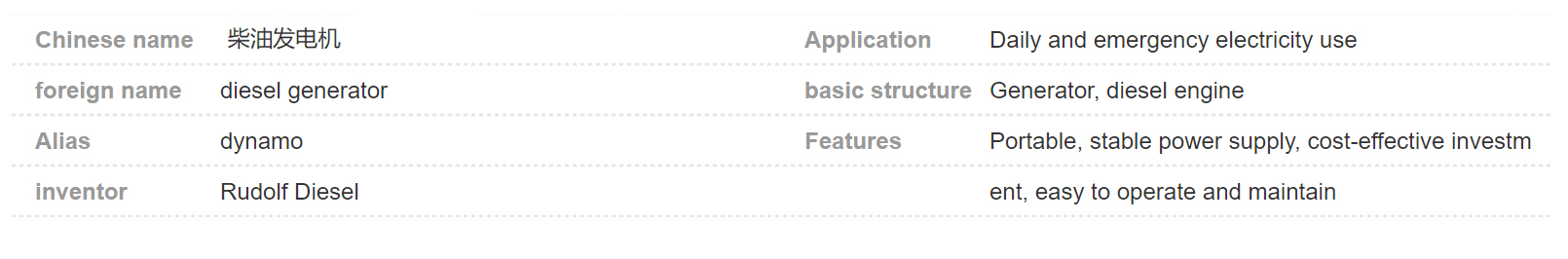

Diesel generator is a small power generation equipment, which refers to the power machinery that uses diesel oil as fuel and diesel engine as the prime mover to drive the generator to generate electricity . The whole unit is generally composed of diesel engine, generator, control box , fuel tank , storage battery for starting and control, protection device , emergency cabinet and other components.

It can be used for daily power generation and emergency power generation in various households, offices, large, medium and small enterprises.

Definition

Diesel generator is a small power generation equipment, which refers to the power machinery that uses diesel oil as fuel and diesel engine as the prime mover to drive the generator to generate electricity . The whole unit is generally composed of diesel engine, generator, control box , fuel tank , storage battery for starting and control, protection device , emergency cabinet and other components.

It can be used for daily power generation and emergency power generation in various households, offices, large, medium and small enterprises.

A generator is a mechanical device that converts other forms of energy into electrical energy .

A diesel generator is a combination of a diesel engine and a generator (usually an alternator) to produce electrical energy. Diesel compression ignition engines are generally designed to run on fuel oil, but there are some types suitable for use with other liquid fuels or natural gas.

The world's first diesel engine was born in Augsburg, Germany in 1897. It was invented by Rudolf Diesel, the founder of MAN. The English name of the diesel engine is Diesel, the founder's name.

MAN is the most professional diesel engine manufacturing company in the world today, with a maximum single engine capacity of 15,000kW. It is a major power supplier to the ocean shipping industry. China's large diesel engine power plants also rely on MAN, such as Guangdong Huizhou Dongjiang Power Plant (100,000 kW). Foshan Power Plant (80,000 kW) are units provided by MAN.

The world's earliest diesel engine is stored in the exhibition hall of the German National Museum.

Basic structure

The basic structure of a diesel generator is composed of a diesel engine and a generator, and the diesel engine drives the generator to generate electricity.

The basic structure of a diesel engine: it consists of cylinders , pistons, cylinder heads, intake valves , exhaust valves , piston pins , connecting rods , crankshafts , bearings and flywheels. The diesel engine of the diesel generator is generally a single-cylinder or multi-cylinder four-stroke diesel engine. Below I will only talk about the basic working principle of the single-cylinder four-stroke diesel engine: the starting of the diesel engine is to turn the crankshaft of the diesel engine by manpower or other power so that the piston is sealed at the top of the cylinder. Make up and down reciprocating motion. The piston completes four strokes in motion: intake stroke , compression stroke, combustion and power (expansion) stroke and exhaust stroke. When the piston moves from up to down, the intake valve opens, and the fresh air filtered by the air filter enters the cylinder to complete the intake stroke. The piston moves upward, the intake and exhaust valves are closed, the air is compressed, the temperature and pressure increase, and the compression process is completed. When the piston is about to reach the apex, the fuel injector sprays the filtered fuel into the combustion chamber in the form of mist , mixes with the high-temperature and high-pressure air, and immediately ignites and burns by itself. power stroke. After the power stroke, the piston moves from bottom to top, and the exhaust valve is opened to exhaust, thus completing the exhaust stroke. The crankshaft rotates half a turn for each stroke. After several working cycles , the diesel engine gradually accelerates to work under the inertia of the flywheel.

The rotation of the crankshaft of the diesel engine will drive the generator to rotate and generate electricity. The generator has a DC generator and an AC generator .

The DC generator is mainly composed of a generator casing, a magnetic pole core, a magnetic field coil, an armature and a carbon brush . Working principle of power generation: When the diesel engine drives the armature of the generator to rotate, the armature coil cuts the magnetic force lines in the magnetic field due to the residual magnetism of the magnetic pole core of the generator . According to the principle of electromagnetic induction, the current is generated by the magnetic induction and output through the carbon brush. .

The alternator is mainly composed of permanent magnets (called rotors) made of magnetic materials with multiple alternating poles (called rotors) and armature coils (called stators ) made of silicon cast iron and wound with multiple sets of series coils. Working principle of power generation: the rotor is driven by the diesel engine to cut the magnetic field line axially, and the magnetic poles arranged alternately in the stator form an alternating magnetic field in the coil core. When the rotor rotates once, the direction and size of the magnetic flux change multiple times. Due to the transformation of the magnetic field, Inductive currents with varying magnitudes and directions will be generated in the coils and delivered by the stator coils.

In order to protect the electrical equipment and maintain its normal operation, the current generated by the generator also needs to be adjusted and controlled by a regulator and so on.